Hugo Reckerth GmbH

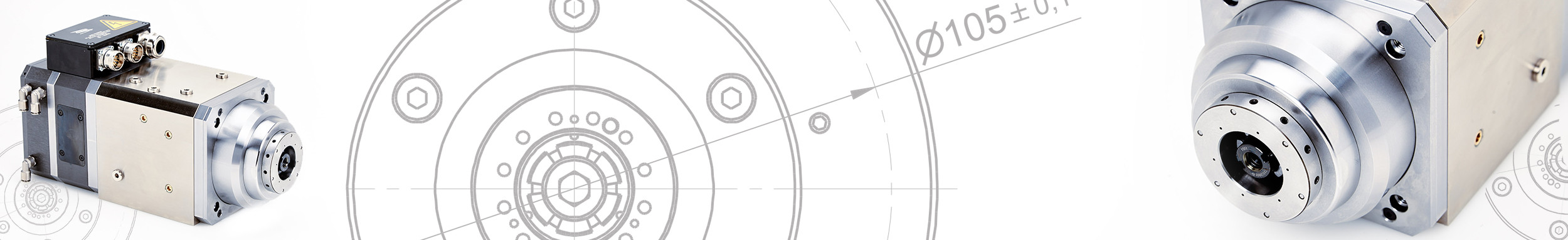

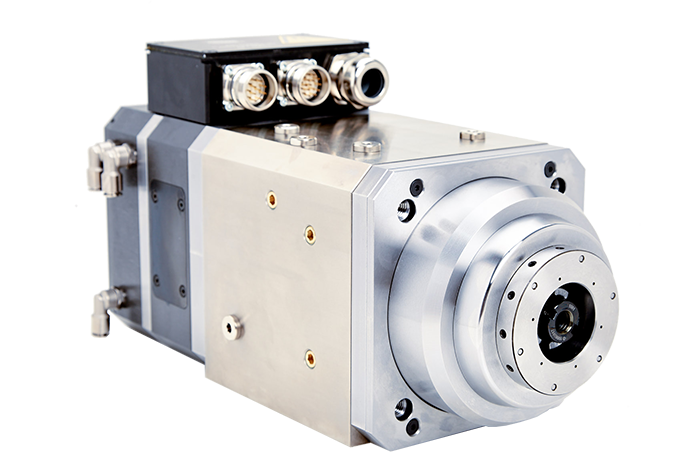

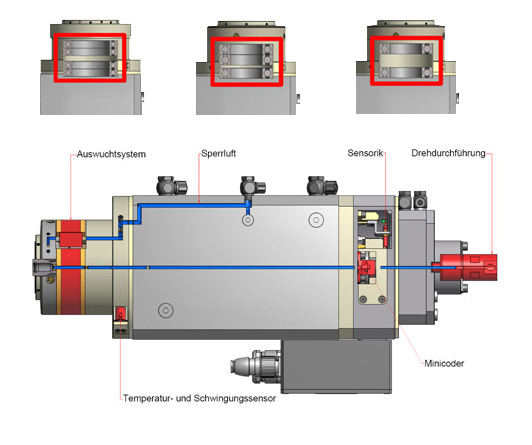

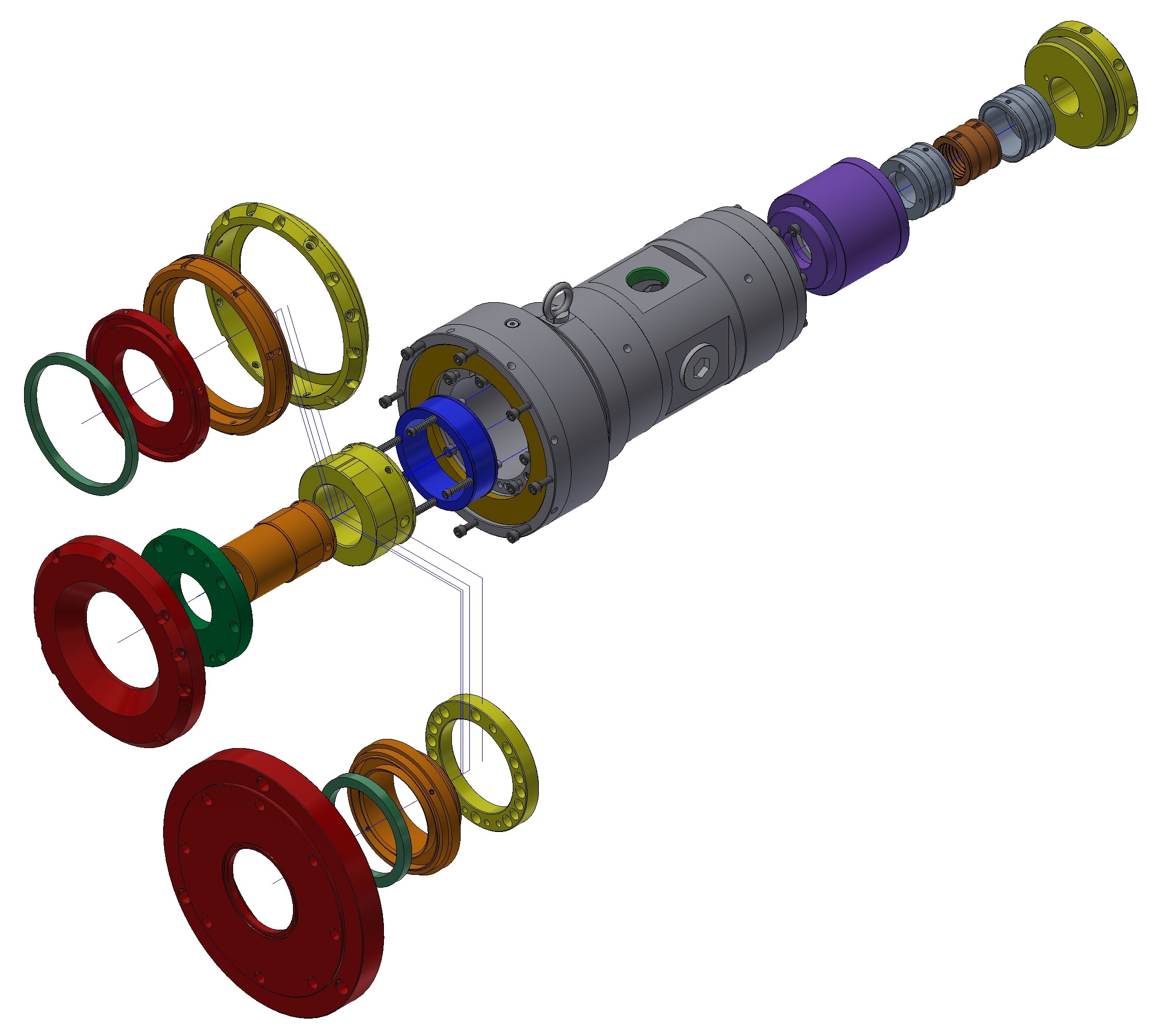

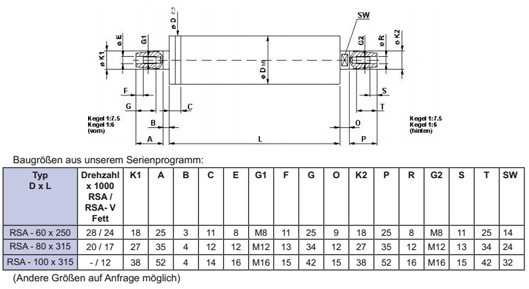

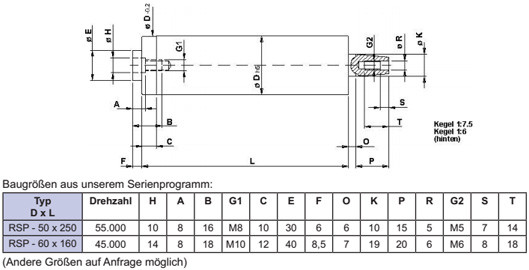

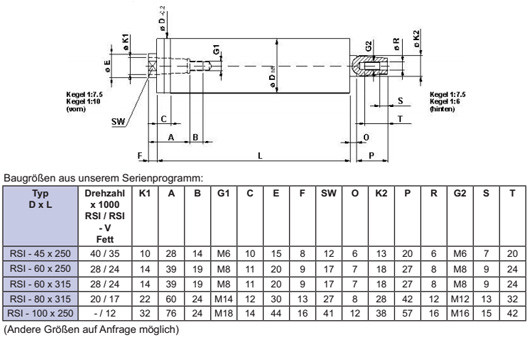

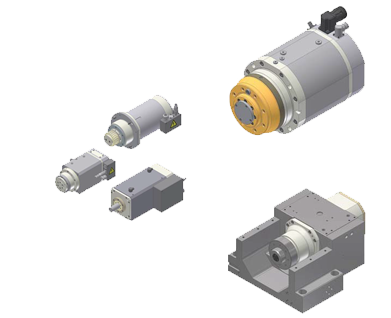

Experience and innovative skills in the design and production of motor, belt and special spindles have made us a high-quality supplier with an international reputation. Our range comprises not only standardized model series, but also individualized and futuristic solutions. Reckerth spindles and Reckerth services are a mainstay of the success of our clients, and a dependable basis when it comes to engineering and services. This is an obligation we honour by meeting the market and customer requirements of both today and tomorrow; and we prove this not least by our regular participation in research projects.